multi-length

-speed

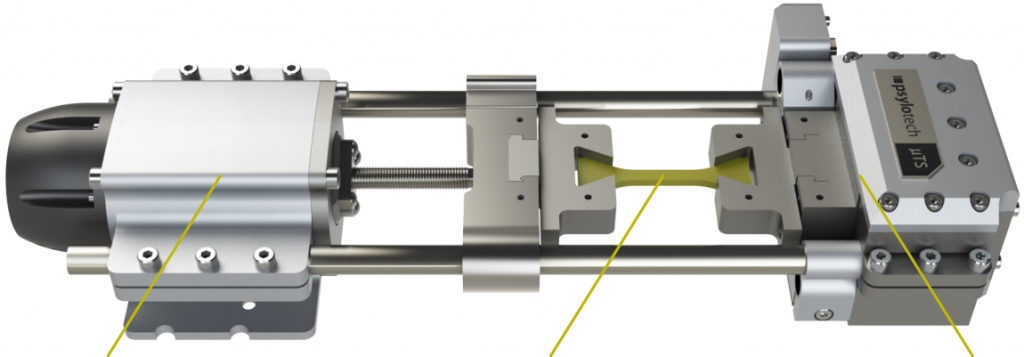

-force scale universal mechanical testing systems

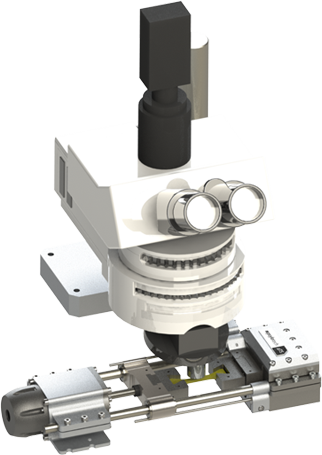

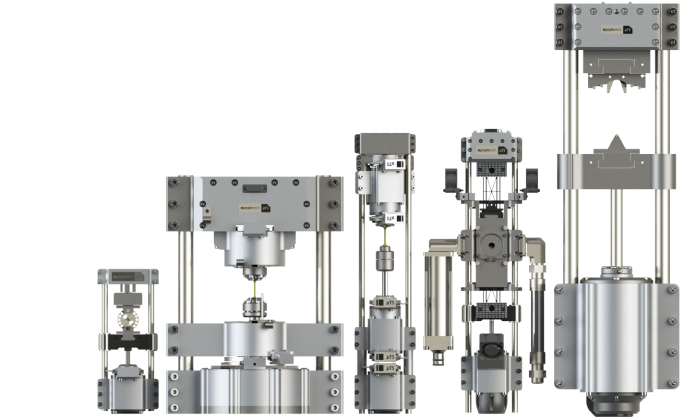

Psylotech designs, builds and integrates mechanical load frames into imaging systems: beamlines, microCT, nanoCT, XRD, and optical, confocal & scanning electron microscopes. We leverage DIC and DVC to characterize materials across length scales. Learn more about Psylotech’s core technologies.

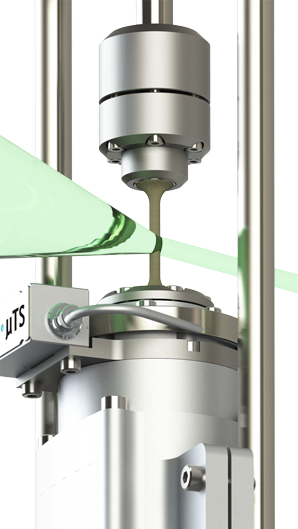

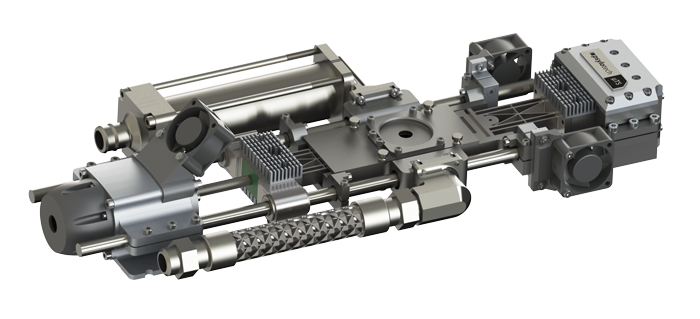

The xTS rotates the load train within the frame, benefiting from Psylotech’s low out-of-plane motion technologies. The rotating load train maximizes microCT spatial resolution and reduces nanoCT scan times. The system is lightweight & portable, and making it ideal for shipping to beamlines. Post imaging software corrects runout and wobble, providing sub-micron spatial resolution.

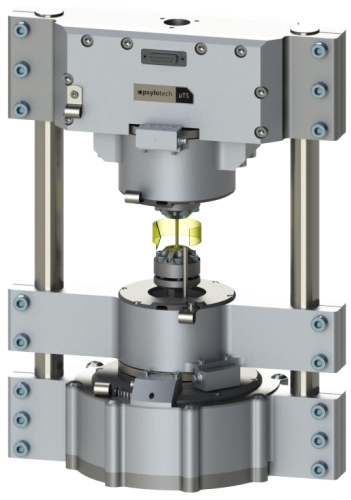

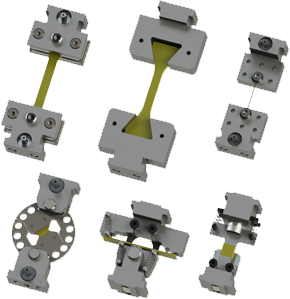

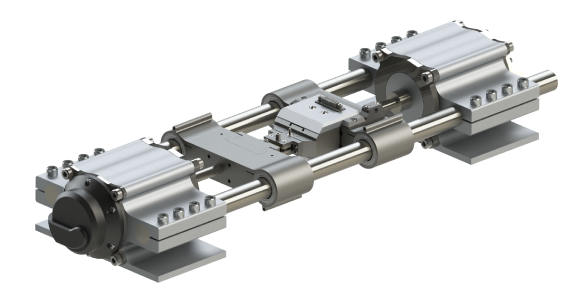

The µTS and xTS can be adapted for XRD. Easily deployable in Synchrotron and Neutron Line applications. Dual actuator option keeps the sample centered in the beam. Extended strokes and temperature chamber options are available.

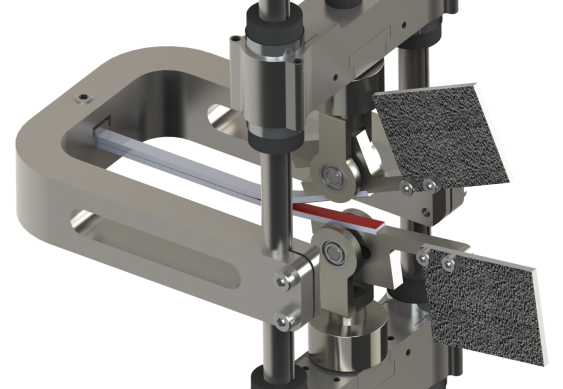

Psylotech has allowed users to develop a more comprehensive approach by developing a dual axis load frame which can provide a wide range of mode-mixes (combination of tension and shear) in a relatively simple manner and leveraging of DIC.

Psylotech offers a microscope-compatible -100 to 300C convective temperature chamber. We also integrate 800 and 1600C furnace designs licensed from the University College London. Laser heating options to 2500C are available to early adopters.

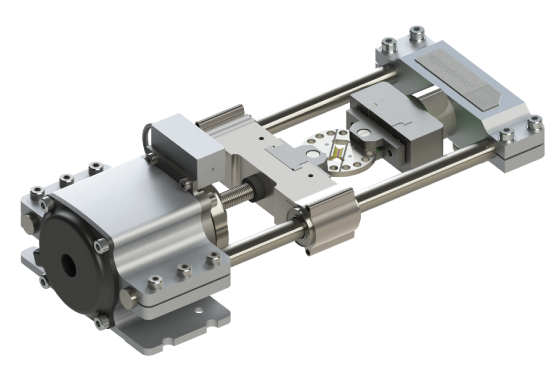

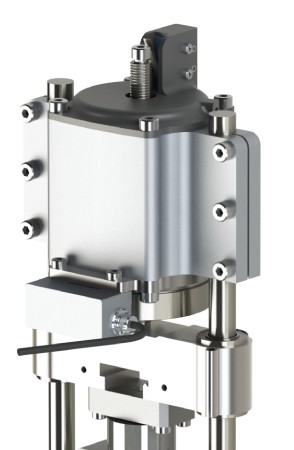

A servo-controlled centering stage keeps the sample’s area of interest under the microscope, even to large deformation. The relative motion is software settable, which is particularly useful when monitoring beam bending samples, where the area of interest is not necessarily half way between the grips. A much lower resolution but more compact stepper centering stage is also available. Alternatively, dual moving cross heads can provide centering.

Implementing a ring encoder enables the stroke to be extended as needed. The extra ball screw length protrudes through the rear of the actuator, enabling stroke longer than the actuator itself.

Sanaz S. Hashemi, Dibakar Mondal, John Montesano, Thomas L. Willett, Effects of biopolymer functionalization and nanohydroxyapatite heat treatment on the tensile and thermomechanical properties of Bone-Inspired 3D printable nanocomposite biomaterials

Hyeyoung Son, Dawson Michael Smith, Zhaofan Li, Taehoo Chang, Wenjie Xia and Chelsea Simone Davis, Particle alignment effects on mechanical properties of cellulose nanocrystal thin films

Zachary Stephen Courtright, Cost-Effective, High-Temperature Materials Testing

Psylotech endeavors to build a world-wide community around multi-scale mechanical testing. Our load frames were designed after the advent of DIC. Our design philosophy is geared to provide experimentalists complete control over their experiments, while concurrently making the default process easy to use. We value quick response time for support and user interactions.

Psylotech was founded in 2006, initially to produce high resolution sensors. With the help and guidance of Prof. Ioannis Chasiotis of the University of Illinois, Urbana-Champaign, we were awarded a 2009 Army Research Lab SBIR with WMRD to build a microscope compatible miniature universal load frame for DIC. In 2018, we built the first rotating load train in situ X-ray tomography for Prof. Hongbing Lu, chair of the Mechanical Engineering Department at the University of Texas, Dallas.

We invite your inquiries. Please send us a message, or contact our sales representatives across the globe.

Psylotech World HQ

1616 Payne St

Evanston, IL 60201 USA

Matthew Struve, Sales Manager

Tel +1 847-328-7100 x 18

Cell +1 847-922-1639

matt.struve@psylotech.com

info@psylotech.com for support or non-sales inquiries

ISG

Office #609, 159, Sagimakgol-ro, Jungwon-gu

Seongnam-si, Gyeonggi-do, 13202

www.theisg.co.kr

TEL. 070-8650-0117

info@theisg.co.kr

Laser Measurement Corporation

OT Building 5F, 1-19-12, Umezato Suginami-ku, Tokyo 166-0011

Telephone +81-3-6304-9600

Facsimile +81-3-6304-9631

info@laser-measurement.com

Alpha Precision Instrumentation Corp.

Room A, 7th Floor, No. 50, Songjiang Road, Taipei City 10455

TEL:02-2511 5959

frank@apic.com.tw

Matthew Struve, Sales Manager

Tel +1 847-328-7100 x 18

Cell +1 847-922-1639

matt.struve@psylotech.com